With Indi Energy’s sodium-ion battery, we can finally end the practice of stubble burning!

Indi Energy has come up with a novel solution to put a stop to the damage caused by Stubble burning, and leading the charge is our sodium-ion battery. October and November are considered to be the most festive months of the year in our nation. In northern India, the ecstatic celebrations are marred by severe pollution levels across the entire region. In this blog post, we will look at what stubble burning is, its consequences, and how Indi Energy’s sodium-ion batteries will pave the way to a sustainable future for us all!

What is stubble burning?

Stubble burning is the process of setting on fire the straw stubble left after the harvesting of grains like paddy, wheat, etc., required in areas that use the combined harvesting method. The farmers burn this crop residue twice a year. In the summer, the smoke dissipates rapidly, whereas, in the winter, it traps half of our country beneath a thick layer of smog due to the cold weather and reduced wind speed, destabilizing our climate and severely impacting our health.

How did the practice of stubble burning begin?

Punjab, Haryana, and Uttar Pradesh led the country’s green revolution in 1966 by encouraging farmers to rotate wheat and paddy crops and utilizing modern technology to boost crop production. It was intended to make India self-sufficient in grain production. In recent decades, mechanized combine harvesters have grown in popularity across the country. The reasons for this are the high labor wages during the harvesting season, a consistent labor shortage, and unpredictable weather. As a result, combined harvesters are the most economical and efficient solution for farmers.

Combine harvesters leave behind a lot of straw stubble that has to be removed; otherwise, it will attract termites and pests that can damage the next crop. The optimum course of action is to let the stubble decompose and turn it into fertilizer, but this can take one to two months. Farmers, however, do not have enough time because the soil needs to be prepared for the next harvest. The manual removal of stubble is also a financial drain for them, and since the paddy residue is high in silica, it makes it unsuitable for it to be used as animal feed. For these reasons, crop residues are intentionally burned, as they are cheap, convenient, and easy to dispose of.

What are the disadvantages of stubble burning?

During the burning process, carbon monoxide, methane, polycyclic aromatic hydrocarbons, and volatile organic compounds are released into the atmosphere, contributing to the nation’s greenhouse gas emissions. In addition, it substantially contributes to winter haze and smog in Delhi and surrounding states by drastically deteriorating the air quality index. Furthermore, stubble burning emits fine particulates that can get trapped in the lungs, causing severe respiratory issues and increasing lung cancer risk. Not only do farmers end up suffering health consequences, but burning crop residue adversely affects soil fertility by killing microbes needed to keep the soil nutrient-rich. Aside from that, the heat from the fire penetrates the soil, increasing erosion and moisture loss. This will lead to more disease-prone crops in the future.

How can we prevent stubble burning?

There have been attempts by the government to prevent stubble burning, even banning it. They have offered incentives and pitched alternatives, such as “Happy Seeders,” a machine that cuts stubble and plants wheat seeds at the same time, but renting it is not financially feasible for all farmers. Despite fines, prison sentences, and other punishments, those who burn crop residue do not seem discouraged.

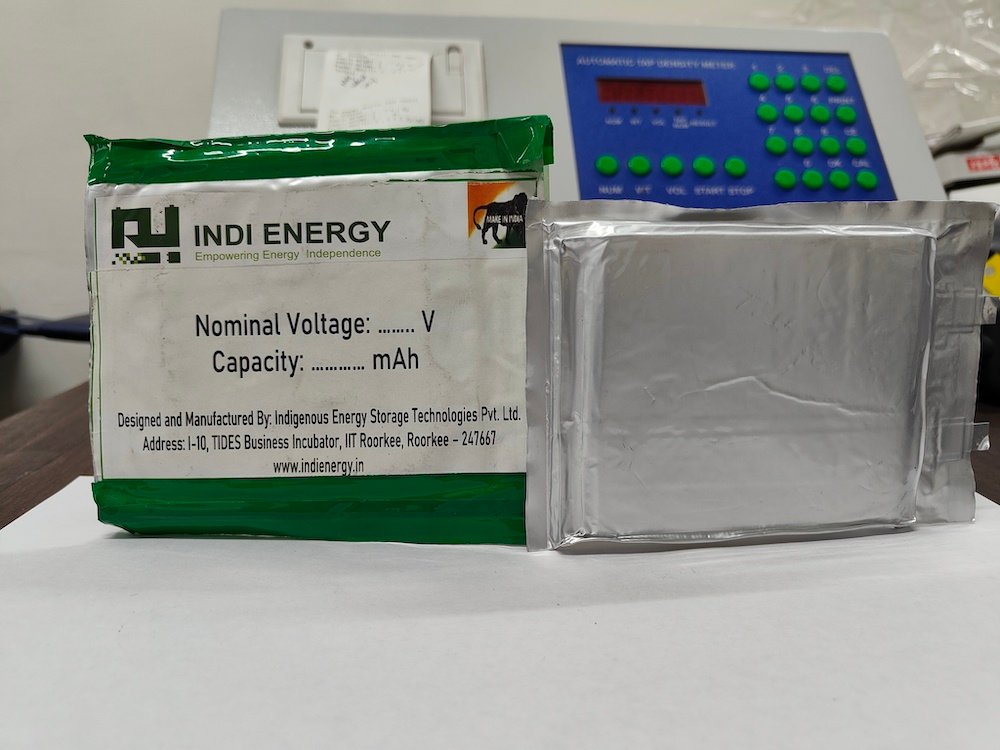

However, we at Indi Energy, an energy storage company based in Uttarakhand, India, have come up with a practical solution that can prevent this from happening in the future. In place of lead-acid batteries and lithium-ion batteries, we have developed our own patented sodium-ion batteries. Each sodium-ion battery from Indi Energy has the distinct advantage of using “hard carbon,” derived from straw stubble and biomass, and has exceptional electrochemical capabilities.

In addition to the fact that biomass is not a scarce resource, we will be able to produce our sodium-ion battery at a fraction of the price, with performance similar to lithium-ion batteries and a much longer lifespan than conventional batteries. It will not only help farmers financially as they can sell their unutilized crop residue, but it is also exceedingly beneficial to the environment since no crop residues are torched. This is one of the key rationales behind our adoption of the moniker “the common man’s battery” to describe our creation.

The advent of Indi Energy has enabled India’s transformation to sustainable, independent, and self-sufficient energy production. We should make the most of this opportunity to reverse ecological damage before it’s too late. Join us, and let’s end the practice of stubble burning once and for all!